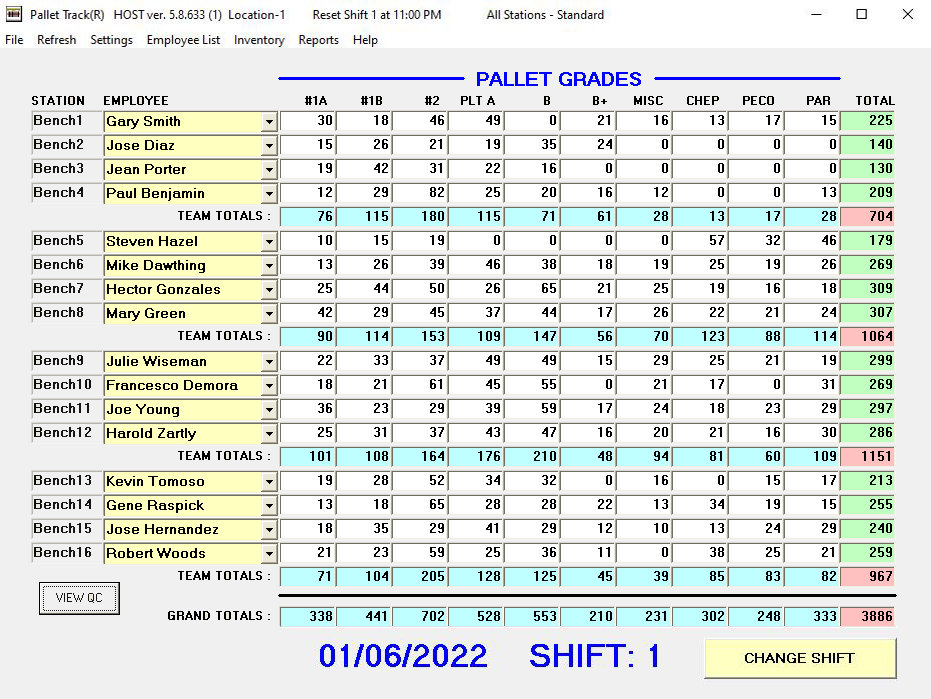

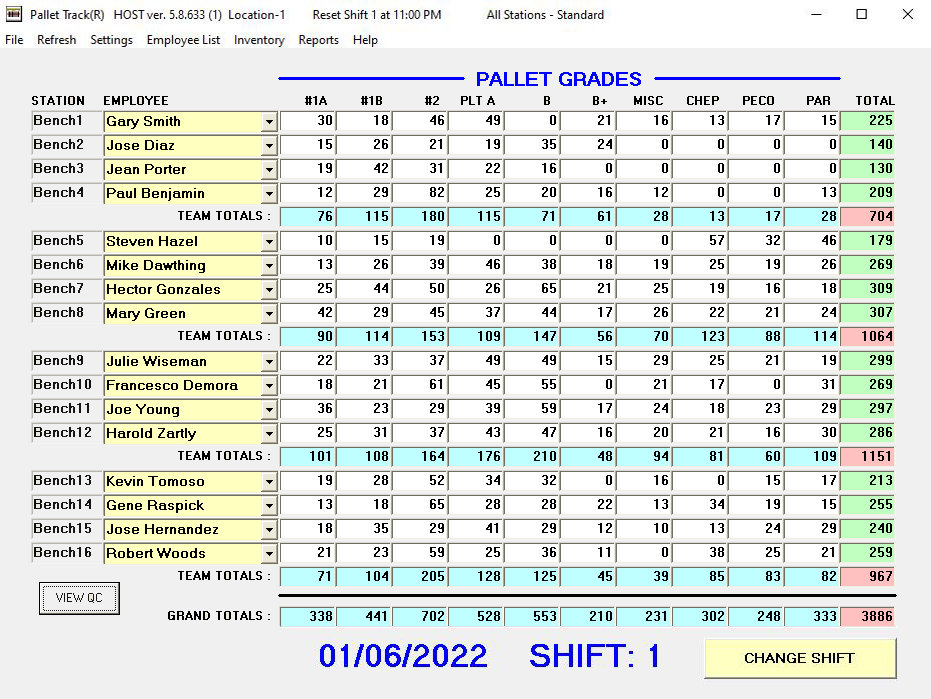

Automated Repair Line

Features & Specifications

Pallet-Track suite of software designed for the pallet industry.

Tracking

- 12 Repair Workstations

- 4 Lead Board Remover Workstations

- 4 Sorter/Quality Control Stations

- 10 Pallet Grades

- Duplicate Scans

How Stations Are Compiled

Individual Repair Stations

- Qty for each grade

- Total of all grades

Lead Board Remover Workstations

- Total production of workstations

- Supplied (customized to line design)

Sorters/Quality Control

- Total production divided by number of sorters

Totals

- Total production of each grade.

- Grand total of all production.

Duplicates

- Total of duplicate tags read by scanner.

Calculations in Report Form

Compensation

- Each repair station employee, based on pre-set piece rates for each grade.

- Each lead board remember employee, based on a pre-set piece rate entered for this task.

- Each sorter/QC employee, based on a pre-set piece rate for this task.

Production

- Separate listing by grade and workstations.

- Summary of all grades

- Total of all grades

Repair Program

- Drives count for Load Repair Kiosk.

- Sets grades for Load Repair System

- Seamless integration

Label Maintenance

- Pallet-Track® Label Printing Software.

- How many labels are left in each dispenser.

Inventory Adjustment

- 1 Graded Pallet is added to inventory for each Graded Pallet produced.

- 1 Awaiting Repair Pallet is deducted from inventory for each graded pallet.

Reports

- Current Production

- Completed Production Details

- Completed Production Summary

- Compensation Details

- Compensation Summary

- Calculated Inventory

- Pallet Repair Programs

- Skipped Labels

- Current Unique Label Numbers

- Remaining Labels

- List Duplicates

Hardware Environment

- Enclosure: Die Cast Aluminum (NEMA 4)

- Operating Temperature: 32°-122°F

- Humidity: Up to 90% non-condensing

- Location: Up to 4000' from Host PC

- Mount: Custom Designed Scanner Stand

Hardware Features

- Industrial NEMA 4 rated scanner

- Up to 1000 scans per second

- Concentrator will buffer up to 1500 scans without losing.

- Information, with no PC